- Banff WWTP Anaerobic Fermenter Mixing

- City of Kamloops WTP Sludge Mixing

- Banff WWTP Polymer Mixing

- City of Penticton WWTP Anoxic/Anaerobic Bioreactor Mixing

- City of Bratford WWTP Scum Mixing

- City of Erin WTP Flocculator

- SilverStar WWTP Anoxic Polishing Tank

Project: Wastewater Treatment Plant

Town of Banff

Waste Water Treatment Plant, 400 Golf Course Road

Box 1260, Banff, Alberta, Canada T1L 1A1

P 403.762.5054<tel:403.762.5054>

C 403.431.0382<tel:403.431.0382>

Client: Banff WWTP, AB

Challenges

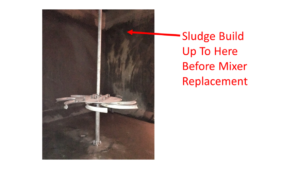

✅ Severe Solids Settlement

-

The sludge from the Primary Clarifiers contains significant amounts of sand and grit, which settle quickly, causing 5–6 ft high sludge accumulation along the tank walls.

✅ Frequent Maintenance

-

In addition to annual oil changes, the submersible mixers require frequent pull-out maintenance to clean ragging and fibrous materials, resulting in high operational downtime and safety concerns.

✅ Air Drawdown

-

The owner’s goal is to use the tank as an anoxic tank for Valentine Fatty Acid (VFA) production. Conventional mixers create vortexes that draw down air, compromising the anoxic conditions required for the process.

✅ Large Amount of Debris in Sludge

-

The presence of large debris increases equipment O&M costs, adding to operational expenses.

Solution

After a detailed Life Cycle Cost analysis, the High Performance Centrifugal Dispersing Impeller (HPCDI) from APMixing Processing Ltd. was selected as the solution.

HPCDI addresses all these challenges by:

✅ Preventing Solids Settlement

-

Its unique flow pattern ensures uniform solids suspension, preventing the build-up of settled sludge and reducing the need for frequent maintenance.

✅ Minimizing Maintenance Costs

-

Designed with low-maintenance features, the HPCDI reduces the frequency of cleaning and repairs, while enhancing reliability and safety.

✅ Maintaining Anoxic Conditions

-

The HPCDI impeller design ensures air is not drawn down, maintaining the ideal anoxic environment required for VFA production.

✅ Handling Large Debris

-

The high efficiency of the HPCDI ensures minimal wear and tear from large debris, reducing O&M costs and prolonging equipment lifespan.

Value Created

✅ Energy Saving

-

The power withdrawal of the HPCDI mixer is about 1.25 HP, representing more than 80% energy savings compared to other products on the market, including the one claiming to be the most energy-efficient.

✅ Satisfactory Performance

-

The HPCDI has superior solids suspension capability. Since installation, no solids settlement has been observed in the tank!

✅ Easy and Safe Maintenance

-

The HPCDI is a top-entry mixer requiring just about 30 minutes for annual oil changes, reducing maintenance downtime significantly.

Energy and Cost Savings Comparison

| Unit | Saving to Competitor 1 | Saving to Competitor 2 | Saving to Competitor 3 |

|---|---|---|---|

| Energy (kWh/yr) | 140,160 | 56,940 | 35,040 |

| Electric Cost ($0.1/kWh) | $14,016 | $5,694 | $3,504 |

| Carbon Reduction (lb/yr) | 185,924 | 75,532 | 46,481 |

-

Competitor 1: Submersible Mixer

-

Competitor 2: Top-Entry Mixer

-

Competitor 3: Invent

Additional Value

In addition to the energy and maintenance savings, the client is now using this sludge mixing tank as a fermenter for the production of volatile fatty acids (VFA), crucial for biological nutrient removal.

-

VFA Production: Estimated at 40–100 kg/day, contributing an additional value of approximately $20,000–34,000 annually.

APMixing’s HPCDI not only provides a cost-efficient solution for mixing but also delivers significant savings in energy, maintenance, and operational costs, while supporting the client’s process goals and generating additional value from VFA production.

Warren Bents

Water Treatment Plant Operator,

City of Kamloops

1315 River St.

Kamloops BC, V2C 1Y8

Phone:(250) 828-3711

Email:wbentz@kamloops.ca

We now have over 700 hours on the HPCD and it has improved the consistency of our centrifuge feed sludge immensely. No any concerns to centrifuges operation.

Project: KCWQ

Client: The City of Kamloops, BC

Problems

✅ Heavy Sludge Settlement

-

Sludge was found settled about 6 ft high along the tank walls, leading to inefficient sludge handling.

✅ Inconsistent Concentration of Sludge

-

The inconsistent sludge concentration sent to the centrifuges caused difficulties in centrifuge operation, affecting overall process performance.

Solution

KCWQ contacted APMixing Process Ltd. to replace the existing mixer with HPCD technology.

Value Created

✅ Increased Tank Volume

-

With the HPCD, no sludge settlement was observed at the tank bottom, increasing the effective volume of the tank.

✅ Consistent Centrifuge Sludge Feed

-

HPCD provided efficient mixing, creating homogeneous sludge in the tank and ensuring consistent feed to the centrifuges.

✅ Improved Centrifuge Performance

-

The consistent sludge feed from the HPCD improved the centrifuge operation, enhancing overall performance.

✅ More than 80% Energy Saving

-

The HPCD consumes 0.704 kW of power, compared to the existing 2 kW submersible mixer, representing more than 80% energy savings.

-

The HPCD runs intermittently for about 25% of the time due to its superior capacity for sludge re-suspension, further reducing energy consumption.

APMixing’s HPCD provided a highly efficient, energy-saving solution that resolved the sludge settlement and inconsistent feed issues, while also enhancing centrifuge performance and maximizing energy savings for The City of Kamloops.

Project: Wastewater Treatment Plant Bioreactors

Client: City of Penticton, BC

Challenges

✅ Insufficient Mixing Performance

-

The existing conventional mixing technologies were unable to provide adequate mixing, leading to ineffective system performance.

✅ Dead Zones or Bypass

-

The presence of dead zones or flow bypasses negatively impacted the system’s efficiency and overall performance.

Solution

APMixing proposed replacing the existing conventional mixers with HPCD technology to create satisfactory mixing performance. The unique flow pattern produced by the HPCD ensures ideal hydraulic conditions, promoting Aerobic Granular Sludge (AGS) formation.

Value Created

✅ Improved Mixing Performance

-

The HPCD technology ensured consistent, uniform mixing, eliminating previous inefficiencies and improving overall mixing performance.

✅ Improved Bioreactor Performance

-

The enhanced mixing led to better bioreactor performance, optimizing the biological treatment process.

✅ Promoted Aerobic Granular Sludge (AGS) Formation

-

The unique dispersing flow pattern provided the ideal conditions for AG formation, enhancing the efficiency of biological nutrient removal and overall system stability.

APMixing’s HPCD provided the necessary performance boost to overcome the challenges faced by the City of Penticton’s wastewater treatment system, improving mixing efficiency and promoting the formation of Aerobic Granular Sludge (AGS) for better treatment outcomes.

Project: Water Treatment Plant Flocculator

Client: Town of Erin, ON

Challenges

✅ Coagulation/Flocculation Performance

-

Proper velocity gradient is critical for effective floc formation. High velocity or shear can break the flocs, negatively impacting system performance.

✅ Dead Zones or Bypass

-

Dead zones or flow bypasses lead to inefficient flocculation and impact overall system efficiency.

✅ Tank Shape Constraints

-

The shape of the tank made it difficult for conventional coagulators and mixers to create the required flow pattern for satisfactory coagulation. Many flocculators required baffles to prevent vortex formation, which resulted in poor mixing.

Solution

APMixing proposed a flocculator with an innovative impeller design featuring extra vanes to create a flow pattern with high flow rate and low flow velocity, ensuring optimal flocculation performance without the need for baffles.

Value Created

✅ Cost Saving

-

By eliminating the need for baffle installation, the solution reduced overall installation costs.

✅ Satisfactory Flocculation Performance

-

The HPCD flocculator provided efficient mixing, ensuring satisfactory coagulation and flocculation performance.

APMixing’s HPCD flocculator delivered an efficient and cost-effective solution for the Town of Erin’s water treatment plant, achieving optimal coagulation/flocculation and avoiding the need for additional baffle installations.

Project: Wastewater Treatment Plant Anoxic Tank

Client: Silverstar WWTP, BC

Challenges

✅ Anoxic Process Requirements

-

The Client required minimal water surface disturbance with no vortex formation and no air drawdown to maintain optimal anoxic conditions for the process.

Solution

APMixing provided the HPCDI-X impeller, specifically designed for oxygen-sensitive reaction mixing, ensuring minimal surface disturbance and preventing air drawdown while maintaining effective mixing.

Value Created

✅ Satisfactory Mixing

-

The HPCDI-X ensured optimal mixing while maintaining the anoxic conditions required by the process. All process parameters met the Client’s specifications.

✅ Minimal Maintenance and Operation Attention

-

The HPCDI-X design required very little maintenance, with the only task being an annual oil change, taking less than 30 minutes each time.

APMixing’s HPCDI-X provided a tailored solution that met the Silverstar WWTP’s anoxic process needs, ensuring efficient mixing and minimal maintenance for long-term performance.